HISTORY

CAPABILITIES

ASSEMBLY

Almost 1/3 of CTR’s facility is arranged, to supply complex aerospace structural assemblies.

Our assembly operations feature the talent to develop the assembly, design original tooling or fixtures and integrate collaboration for problem-solving, all in order to deliver a perfect value-added activity to our customers.

ASSEMBLY DETAIL

- Bulkhead

- Keel Beam

- Seat Track

- Racks

- Doors

- Kitting of Detail Parts

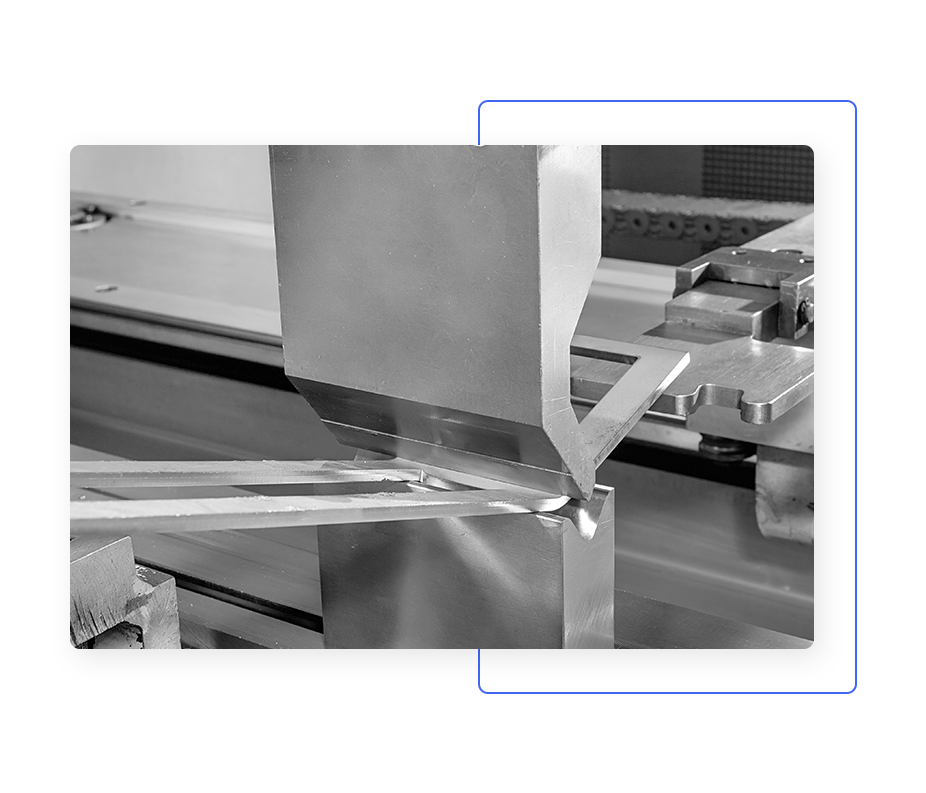

CNC FORMING

CTR’s skilled operators are extensively trained in programming and operating in order to provide consistent, accurate bends and forms every time. CTR has extensive experience and training in regards to metallurgy and the equipment used for precision CNC sheet metal forming and we are well trained to provide exceptional service so that all metal forming products meet or exceed our customers’ expectations.

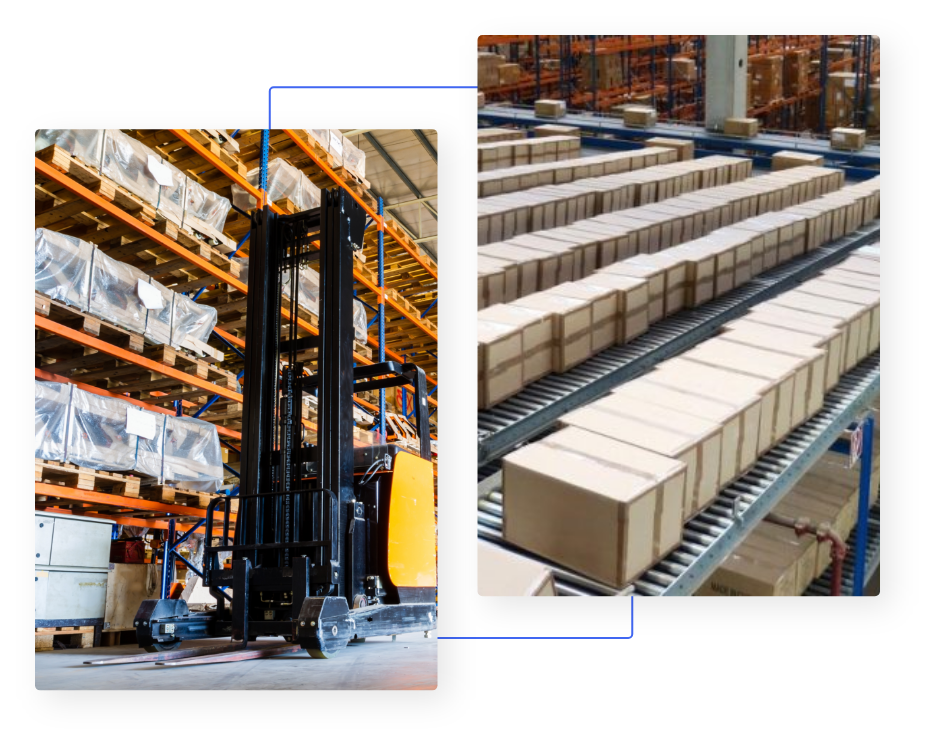

KITTING

In support of our customer’s lean and Best Practice’ Initiatives, CTR offers kitting services to help streamline the flow of components to their assembly lines. CTR’s kitting service provides our customers with the parts they require in convenient, easy-to-read packaging precisely when they need it. CTR takes pride in saving our customers time and money with lower administrative costs and less inventory on their shelves.

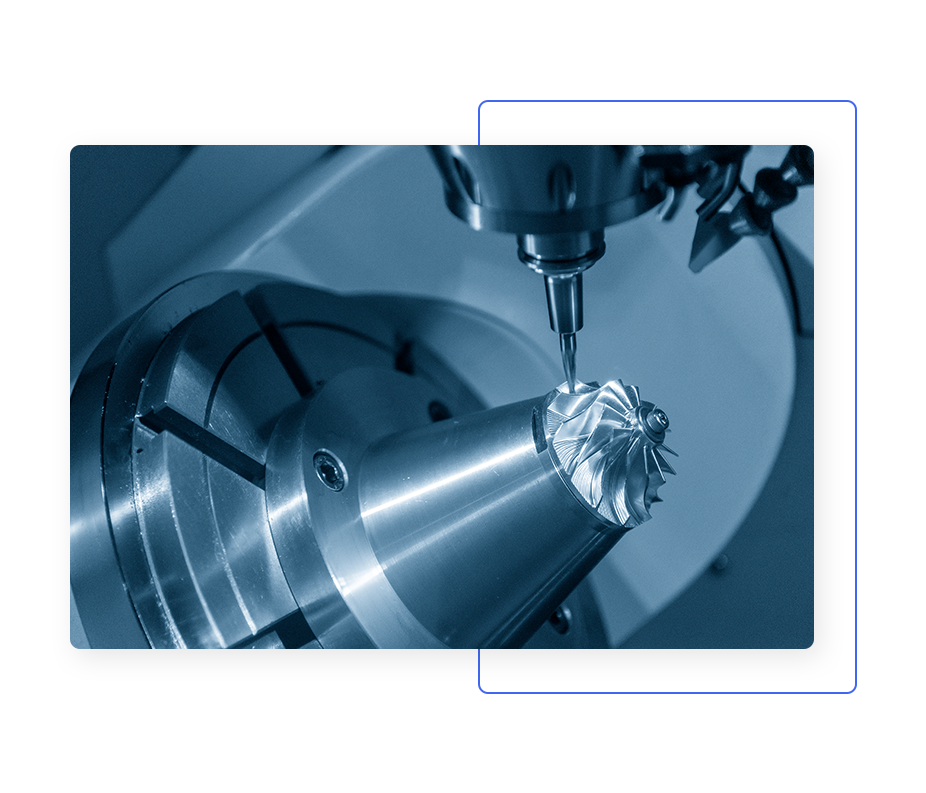

CNC MACHINING

MACHINING DETAIL

- 3, 4, and 5-axis complex and contoured machining utilizing new, well-maintained CNC mills

- Latest-available technology including Renishaw probe readiness and pallet-changing on most equipment

- Tool Life Management program in place utilizing pre-setter, tool verification, balanced heat-shrink holders, and latest cutter designs and materials, allowing for increased tool life, better surface finish, closer tolerances, and faster metal removal rates

- Ample 5-axis aluminum size capacity with length over 120″ on multiple machines

- Hard metal experience including inconel, titanium, Aermet 100, 13-8, 15-5 and 17-4

MACHINING PRODUCTS

- Beams

- Braces, Intercostals, Stringers, Struts, and Webs

- Complex Fittings and Attachments

- Doors and Access Panels

- Keels and Bulkheads

- Mechanical Components and Structural Details

- Ribs

- Seat Tracks

- Flap Tracks

ENGINEERING

With the rapid advancement in aircraft technologies, CTR continues to make sure we are able to meet our customers’ current and future needs by constantly upgrading and improving our capabilities and facilities through the ongoing acquisition of the most technologically advanced equipment in the industry. Combined with a commitment to the continuing education and improvement of our workforce, CTR is positioned to meet the challenges of the evolving needs of the aircraft industry.

TOOL DESIGNING & PROGRAMMING DETAIL

- Intricate (complex, compound contoured) forming tooling and multi-axis NC code designed and developed in CATIA Advanced Manufacturing software

- Extensive experience in Model Based Definition (MBD)

- Modern data administration infrastructure with Digital Production Definition (DPD) approval from most primes

- Up-to-date support software with data integrity and cutter path validation tools such as Capvidia and Vericut